Case study

Optimizing the vehicle hauling schedule

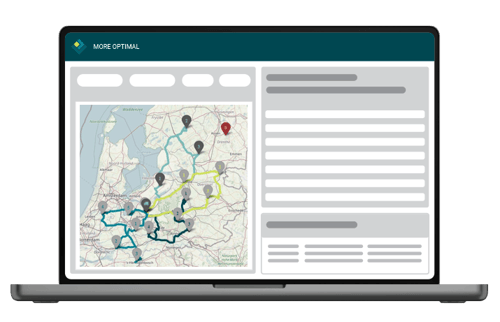

Vehicle hauling is a complex process that requires careful planning and optimization. With multiple constraints such as vehicle capacities, order priorities, driver requirements, pickup- and delivery time windows, it can be challenging to find the best route for each truck. That's where More Optimal comes in.

The challenge

Our customer, a large vehicle hauler with 100 trucks, faced several challenges in their day-to-day operations while shipping 500+ cars per day across Europe. One of the most significant challenges was combining cars of different sizes onto one truck while following strict pickup and delivery time windows. The uncertainty of orders for the next day, which were only known at 8 PM, made it difficult to decide on the number of external trucks to hire. Additionally, the trucks do not return to the home location every day and drivers spend the night at one of the allowed overnight locations, adding to the complexity of the operations.

To overcome these challenges, the operations manager chose More Optimal Software, an advanced route optimization tool. The software helped the planner to optimize the overall puzzle and made it easy to run quick what-if scenarios. The parallelized solver technology of More Optimal allowed the company to optimize multiple pieces of the puzzle in parallel and then combine them into a global solution for maximum efficiency.

100+

trucks

8%

reduction in distance

10+

specific planning rules

The results

By implementing More Optimal Software, the vehicle hauling company was able to optimize its operations and achieve remarkable results. The company recorded a 8% reduction in travel distance while delivering more orders on time, providing a tangible and measurable improvement in their operations.