Container terminal planning

Optimize your terminal

Want to improve the efficiency of your reach stackers? Is it a real challenge moving containers into storage while at the same time loading other containers for delivery? Where can I place this container to avoid restacking it later? Which container should I dispatch next? More Optimal has the solution!

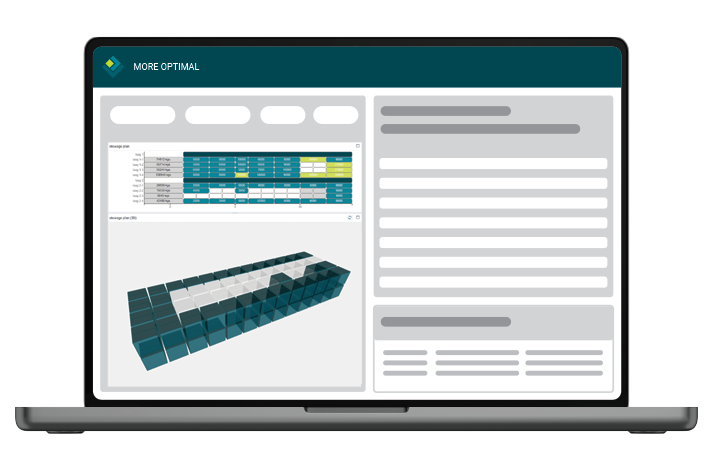

Optimize your container terminal with smart algorithms and powerful visualization

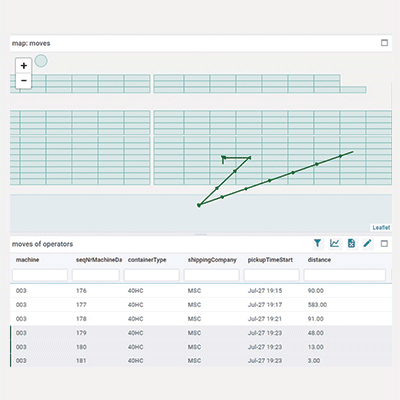

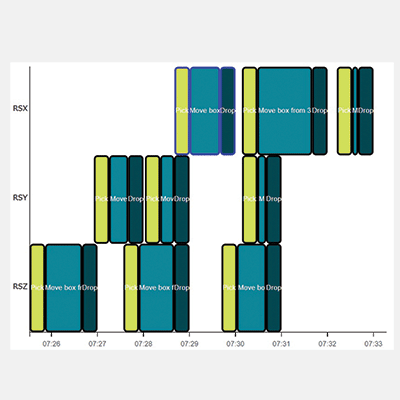

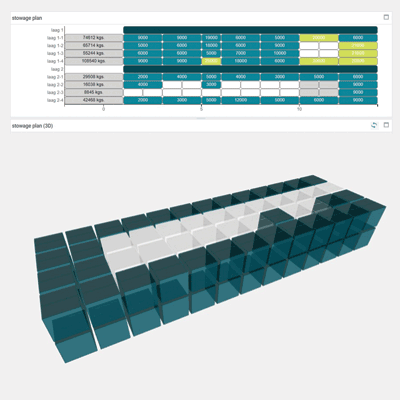

How do I optimize container moves? Some examples… after a truck delivers a container, which container should it pick up next? Unloading which container in what order is more efficient overall? Where should you stack containers to facilitate operations later on? Where should reach stackers be deployed in what sequence to save time and costs? A Terminal Operating System (TOS) contains a basic planning module that uses simple heuristics.An operator must make decisions on the spot based on their experience and knowledge without access to the bigger picture. The reduces efficiency and even creates bottlenecks. The TOS is helpful, but it cannot provide deep insight into efficient long-term planning. And this is exactly where More Optimal excels. Use powerful visualization to boost your profits while cutting costs. Our powerful optimization technology can reduce costs by more than 10%.

Find out how to increase your terminal efficiency by 15%

Container terminal optimization features

Crane scheduling

Reach stacker scheduling

Stowage plan

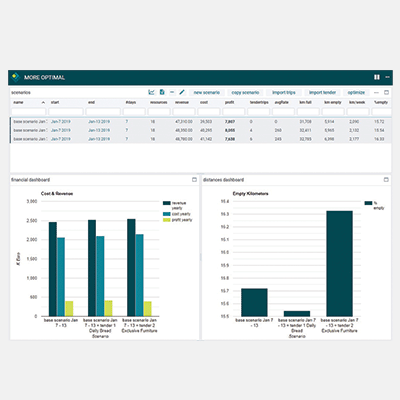

Scenario comparison

Smart solutions for complex challenges

More Optimal takes container terminals to the next level of optimization. Use powerful visualization tools to glean a deeper understanding of your operations and optimize your planning to the utmost.

Our customer-focused solutions generate insights at the strategic level (e.g., capacity and cost when customer mix changes) and the operational level. KPIs are always balanced to ensure your operations are optimal for you and your customers.

Frequently Asked Questions

Yes. All of our terminal operators store their transactional data in a TOS that utilizes rules and constraints. Our smart solutions use world-class optimization technology to enhance your logistics planning beyond the TOS’ capabilities. Our software platform takes your specific rules and constraints into account when optimizing planning solutions for your supply chain problems.

Our flexible interfacing technology communicates with any TOS either directly or via the enterprise service bus. In technical terms, we typically use JSON over REST APIs to interface with a TOS. Contact us to learn more about other interfacing options.